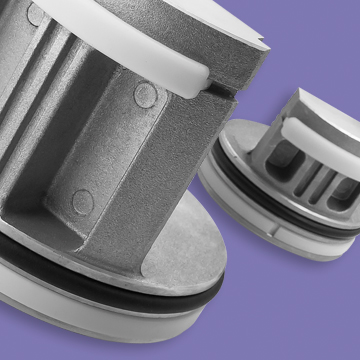

The items are made by cold-die cutting different made-to-drawing designs from a rubber sheet (produced by calendering) or other materials (e.g. Flexoid, felt, Teflon). The sheets are cut using metal moulds (dies) mounted on specific machines (die cutters).

As with hot moulded or cold-spliced items, the DIE CUTS have excellent physical and mechanical features, as well as being elastic and aesthetic and ensuring a sound seal. The die is typically used to make flat items such as frames, disks, and washers.

The articles can be die-cut on demand and coupled with an adhesive film. They are particularly suitable for lighting and plumbing.

Tolerances allowed for punched items in both sponge and solid rubber:

UNI EN 22768-1 class m (linear dimensions)

DIN ISO 3302-1 class E2 (thickness)