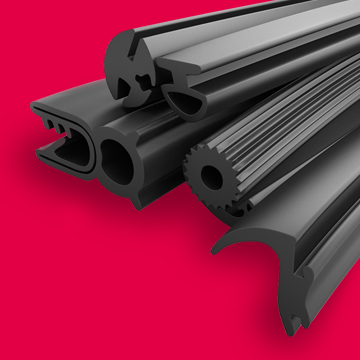

EXTRUDED articles are essentially tubes and profiles in different sections. They are produced in an extruder where the raw compound is loaded into a heated extruder, and then pushed through a ring nut in order to have the desired shape and size. The subsequent vulcanization takes place in a horizontal furnace, which allows for complete crosslinking. The profile is then wound into coils or cut to size.

These items are particularly suited to lighting and electronics. Upon request, extruded profiles can be cut into different lengths.

For certain applications extruded profiles can also be cold glued, using special glues, or hot with a procedure called splicing systhem, so that the finished article has the exact size required.

Extrusion has wider tolerances than moulding in accordance to DIN ISO 3302-1 classes E2 (section) L2 (length).