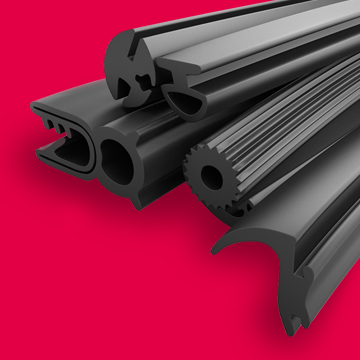

INJECTION moulding is carried out through horizontal and / or vertical presses. The raw compound is loaded, raised to the right temperature, and then injected into a metal mould where it is cured for a predetermined time. This procedure is particularly suitable for manufacturing large series of technical products and o-rings.

COMPRESSION moulding always takes place in a metal mould, the raw compound is loaded manually. This process is suitable for producing smaller quantities of large sized and heavy items.

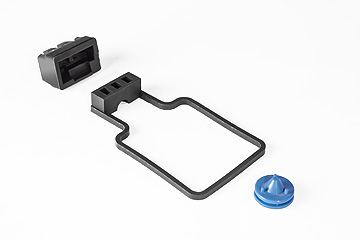

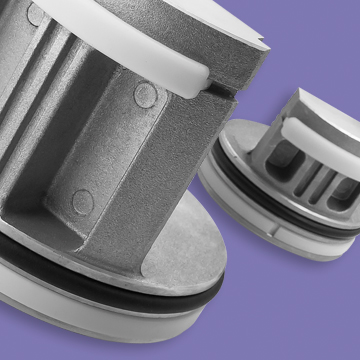

The two systems can be used to co-mould rubber and plastic or rubber and metal, supplied by the customer or made-to-drawing. These items are particularly used in the lighting, electro medical, automotive, electronic, pneumatic, and food industries.

Tolerances allowed for injection and compression moulded parts:

SO 3302-1 class M2 O-Rings: ISO 3601-1.